+86 15633683072

When people search for “how to Tig weld stainless steel pipe”, most guides give the same answers: clean the joint, control the heat, protect the weld.

All of that is true—but it’s incomplete.

From our experience as a manufacturer of automatic pipe welding equipment, the real challenge of TIG welding stainless steel pipe is not knowledge. It’s repeatability under real production conditions.

This article focuses on what actually affects weld results when stainless pipes move from one-off welding to real manufacturing.

In theory, stainless steel pipe TIG welding is stable. In practice, weld failures often come from small, accumulated deviations.

We see three common issues when customers ask us how to tig weld stainless steel pipe more reliably:

Inconsistent torch travel speed

Fluctuating arc length

Unstable gas shielding at the root

These issues don’t show up immediately—but after dozens of joints, weld appearance and penetration start to vary. That’s where many stainless steel pipe welding companies run into trouble.

Many welders assume pipe size only changes current settings. That’s not enough.

During tig welding 1 inch stainless pipe, heat accumulates extremely fast. Even slight pauses can cause excessive penetration or distortion.

With tig welding 2 inch stainless pipe, the problem flips—heat spreads unevenly, and weld consistency depends heavily on torch angle and movement rhythm.

In both cases, mastering how to tig weld stainless steel pipe means controlling motion just as much as current.

This is why more workshops begin testing automatic pipe welding equipment once production volume increases.

Thin-wall applications raise the difficulty again.

Tig welding stainless tubing and tig welding stainless steel tubing leave almost no margin for error.

A slight fluctuation in heat input can collapse the tube wall or discolor the weld.

From our internal welding tests, manual control works only within short time windows. Once fatigue sets in, consistency drops fast—even for experienced welders.

That’s one reason orbital welding stainless steel pipe has become standard in tubing projects requiring clean, uniform welds.

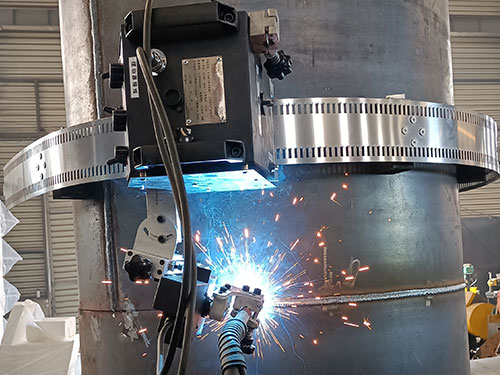

Orbital welding stainless steel pipe doesn’t replace TIG welding—it stabilizes it.

Instead of relying on hand movement, the system controls:

Travel speed

Arc length

Heat input

Shielding timing

For customers asking how to tig weld stainless steel pipe with consistent results across hundreds of joints, orbital systems often become the turning point.

This shift is especially visible among stainless steel pipe welding companies working in pharmaceuticals, food processing, and high-purity pipelines.

From a factory perspective, automatic pipe welding equipment isn’t about speed alone—it’s about removing variables.

When we test welding programs in our lab, we can reproduce the same weld dozens of times with minimal deviation. That level of control is nearly impossible to maintain manually over long shifts.

For manufacturers, understanding how to tig weld stainless steel pipe eventually means accepting that some variables must be engineered out of the process.

As a factory specializing in automatic pipe welding equipment, we design systems around real welding behavior—not textbook theory.

Whether it’s tig welding 1 inch stainless pipe, tig welding 2 inch stainless pipe, or precision tig welding stainless steel tubing, our goal is always the same:

make TIG welding predictable, repeatable, and production-ready.

That’s the difference between knowing how to tig weld stainless steel pipe and being able to deliver the same weld quality every single day.

Zhengzhou Kehui Technology Co., Ltd

Email: info@zzkehui.com